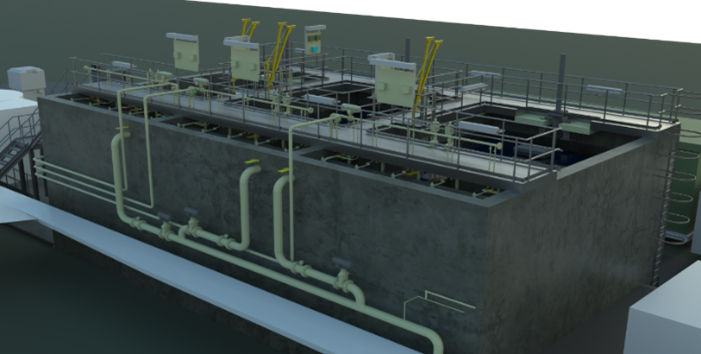

Southern Water’s Tangmere Sewage Treatment Works treats domestic wastewater from villages to the east of Chichester: a population of around 800.

The treatment process consists of three biological trickling filters each with a humus tank to remove suspended solids and clarify the effluent prior to discharge. The accumulated sludge was removed from the humus tanks by three dedicated progressive cavity pumps drawing from the humus tank sludge withdrawal pipework within the desludge chamber and discharging back into the desludge chamber and to the gravity sludge drainage system. This desludging system suffered from ‘rat holing’ where the suction created by the pump drew water preferentially, leaving sludge solids in the humus tanks. The result was dilute sludge with a high water content being discharged to sludge storage or requiring further treatment which increased operational costs on the site.

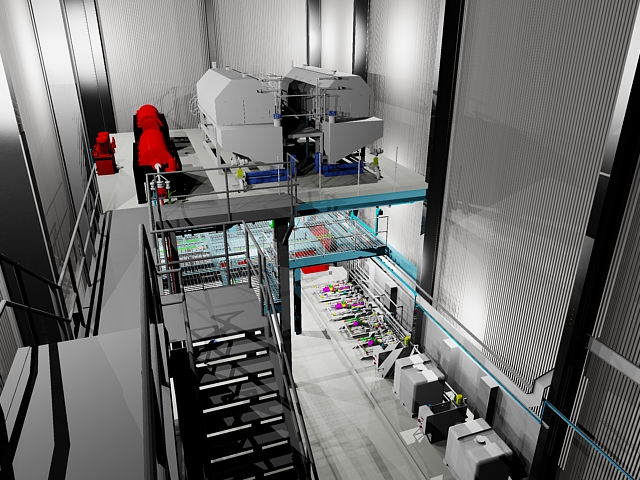

Typically for each of the three humus tanks the pumped desludging system comprised of progressive cavity pumps, suction pipework and control valves, discharge pipework and associated pressure instrumentation, cable and tray work, local isolation enclosures and power and signal cabling from a remote MCC with pump starter cubicle and associated controls.

Improved Desludging

To improve the desludging Southern Water decided to replace the existing pumped desludging with a single te-sewpasTM pulsed airlift desludging unit serving all three humus tanks. The system has a single 4.6kW duty side channel air blower, actuated air control valves, air manifold and control panel housed within a weatherproof GRP enclosure which is delivered to site fully assembled and tested.

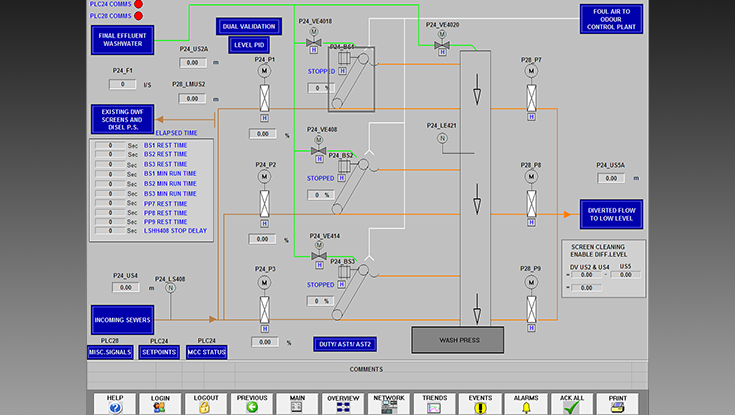

The pulses of air within the sludge withdrawal pipe have the effect of consolidating the sludge upstream, effectively eliminating any potential ‘rat-holing’ within the pipework. The PLC/HMI control of the te-sewpasTM allows the air pulse durations and sludge recovery frequency and duration to be adjusted to suit each of the individual humus tanks.

Te-Tech's Pulsed Air Desludging System

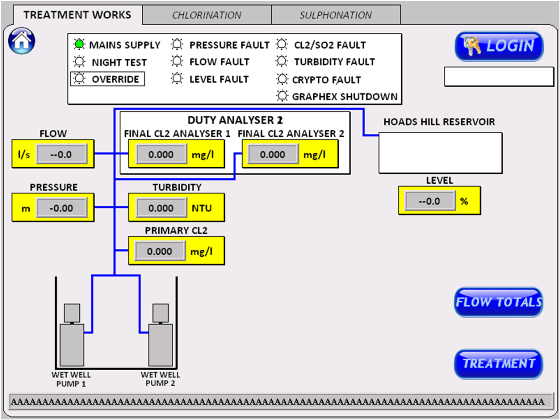

The te-sewpasTM desludging equipment is a self-contained unit which operates on the principle of an intermittent air lift. Adjustable timers incorporated within the control panel operate a solenoid valve fitted in the air discharge pipework. This controls the amount of air delivered to the sludge discharge pipework and the time delay between desludging events. Each charge of air lifts a quantity of sludge and discharges from the sludge discharge pipe, whilst the variable delay ensures that sufficient time elapses for the sludge to recover or refill the sludge pipework, to ensure consistent desludging. A multi-timer incorporated within the Control Panel, enables the unit to be programmed to desludge at any selected interval to satisfy the specific needs of each site. The system can also be operated and monitored remotely by the client’s control system.

The unit can be located close to the tanks that it serves with flexible air delivery hoses routed through ducts to each of the desludge chambers. The air delivered is hot and hence there is no need for thermal lagging or insulation. Each unit can serve up to four primary or humus tanks with typical individual air delivery hose length up to 35 metres.

Cost Savings

The te-sewpasTM system provides significant whole life cost savings when compared to conventional pumped systems. For a typical installation serving three tanks like Tangmere, te-sewpasTM provides a 40% lower capital cost and 50% reduction in operational cost based on an estimated 25% reduction in the electrical power consumption and reduced maintenance requirements compared to a pumped desludge system.

> 25% reduction in electrical consumption

> 65% reduction in maintenance labour hours

> 50% reduction in spares and consumables

> 25% reduction in operator attendance

Contact Us for more information or to talk about your requirements email enquiries@te-tech.co.uk

te-sewpas Benefits

✔ Reliable sludge extraction

✔ Low energy demand

✔ Low maintenance

✔ Simple desludging interval adjustment

✔ No moving parts in contact with sludge

✔ Easy non-invasive retrofit

✔ Ability to use existing pipework and power

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)