Design and manufacture of a 'U' shaped Form 4 motor control centre.

A 15m-long, U-shaped 600amp motor control centre (MCC) with dual supplies was installed. The MCC was fed from two separate transformers, incorporating a change-over compartment, providing security of supply to the works. The (form 4 type 2) MCC was located in a purpose-built MCC room within the ST&D building. The U-shaped MCC was required to enable it to fit within the existing building layout.

The MCC functional units included the following:

- Mains Incomer Sections with Castell interlocking and metering section.

- Variable frequency starters using ABB ACS550 VFD’s.

- DOL starter sections.

- ASD starter sections.

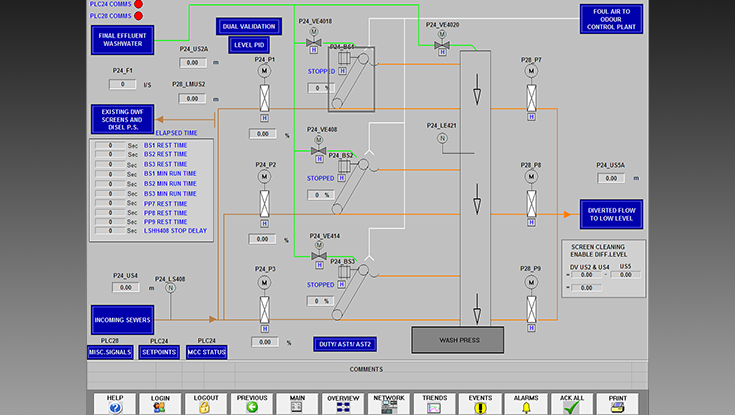

- Common Controls section containing Mitsubishi Q series. PLC and E1151 Pro+ HMI allowing full automatic control of sludge thickening and dewatering process.

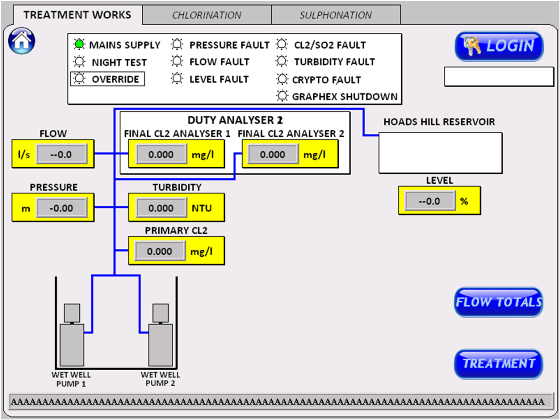

- Software development and HMI Graphics.

- Full Factory Acceptance Testing (FAT) prior to delivery.

- The supply of full documentation including Declaration of Conformity Certification confirming adherence to BS EN 61439-2:2011, LV Directive and the EMC Directive.

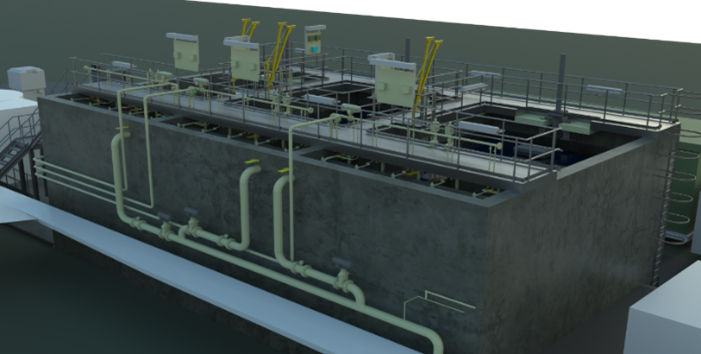

We were responsible for the detailed design of the process and MEICA aspects as well as undertaking the Civil, Mechanical engineering, Electrical installation and commissioning. We designed, manufactured, installed and commissioned the new sludge motor control centre (MCC). Plus, also developed the MCC software, integrating it with existing system architecture and SCADA systems.

Key Figures

| Population Equivalent | 110,000 |

| BOD Load | 7950 kg/day |

| SS Load | 9500 kg/day |

| Primary Settlement Tanks remove:- | -65% SS 35% BOD |

| Secondary SAS Production (Dry Solids) | 4400 kg/day |

| Secondary SAS | 0.4% to 1.0% Dry Solids |

| Primary Sludge Production (Dry Solids) | 6175 kg/day |

| Primary Sludge from PST’s | 3% Dry Solids |

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)