Southern Water are required to meet tightening discharge consent requirements and growth drivers as part of their AMP7 capital delivery programme.

The quality drivers set out in the Water Industry National Environment Programme (WINEP) for Hawkhurst are to meet new iron and total phosphorous discharge permits, a tightened ammonia permit and an increase in flow and load to cater for population growth.

In addition to the tightening consent and growth requirements, it was also important to maintain compliance with all aspects of the current discharge permit during construction and prior to the decommissioning of the existing biological trickling filters and humus tanks.

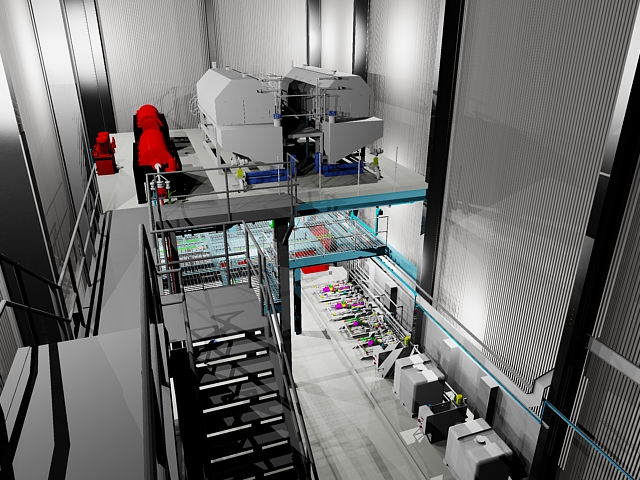

The restricted site availability for the new treatment works and ongoing operation security requirements were key considerations during feasibility and subsequent detailed design.

The site was also adjacent to a protected ancient woodland and provided a diverse wildlife habitat for badgers, bats and birds. To minimise disruption and to ensure sustainability the design had to be adapted to preserve the woodland and habitat.

The Solution

In response to Southern Water’s requirements a single stage te-cycTM process was selected to replace the existing biological trickling filters and humus tanks, re-using some of the existing assets where appropriate and practical.

Due to the tight site constraints and the need to achieve multiple drivers with a low Totex solution, the te-cycTM process was selected due to its small footprint, reduced chemical consumption and its ability to treat ammonia and phosphate in a combined process stage.

In addition to the core te-cycTM process stage, the wider project scope included the design and construction of the feed pumping station, Ferric storage and dosing equipment, modifications to the existing inlet and primary treatment works, MCC, standby generation facilities and a new power supply was to be provided.

Process Description

The te-cycTM process, with over 500 reference sites worldwide, is an advanced cyclic activated sludge process achieving simultaneous carbonaceous, nitrification, denitrification and biological P removal.

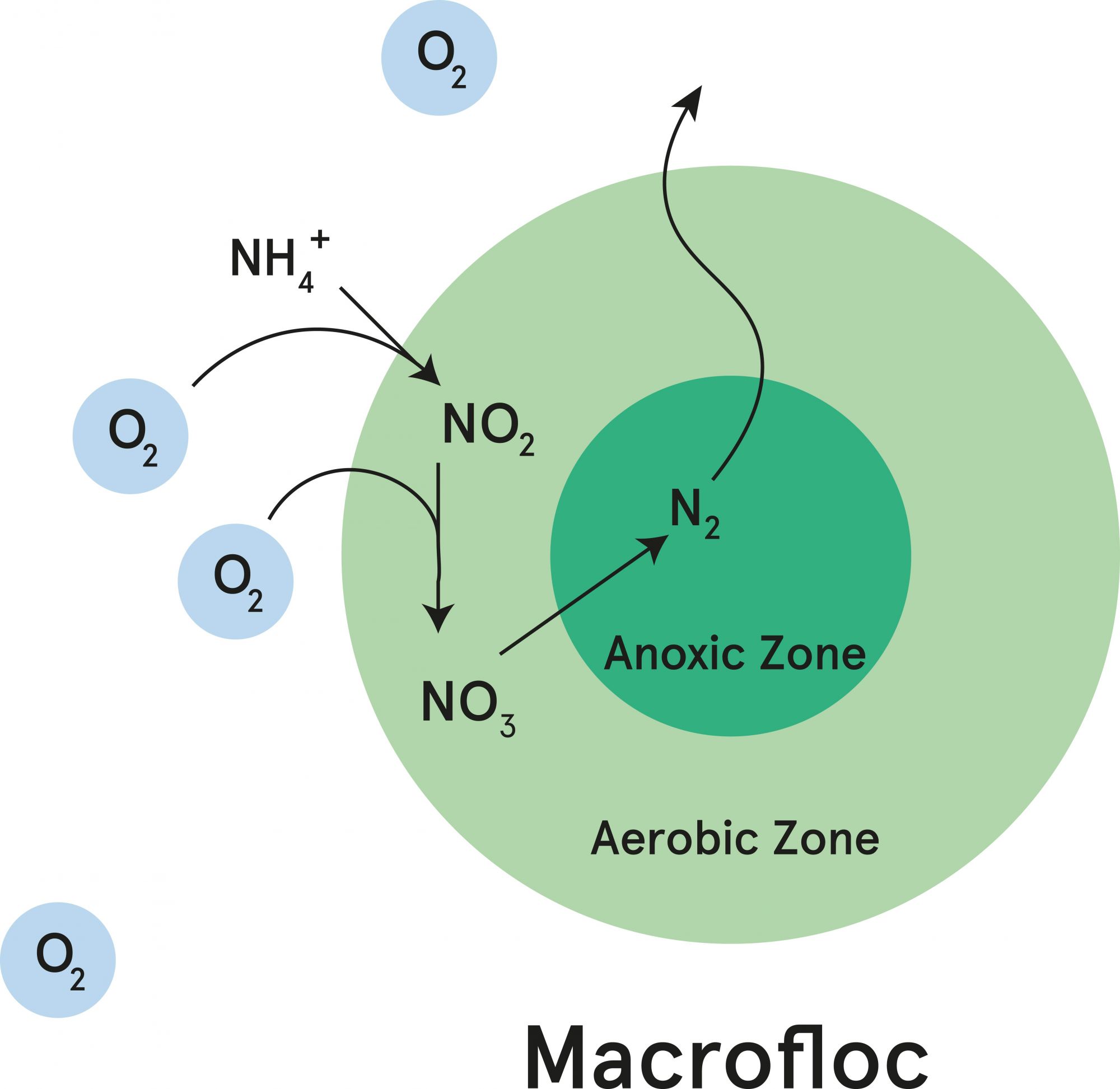

The te-cycTM process incorporates an anaerobic selector zone, which suppresses the growth of bacteria that cause sludge bulking and includes internal recycling of the biomass to the main reactor zone to create the formation of ‘macroflocs’.

In the te-cycTM configuration these larger macroflocs form an internal anoxic zone and external aerobic zone and contain polyphosphate accumulating organisms or PAO’s. On the macrofloc surface, bacteria act to convert ammonia to nitrate whilst the PAO's take up phosphorus from the surrounding liquid. Inside the macrofloc, anaerobic bacteria convert the nitrate to nitrogen gas, which escapes harmlessly to atmosphere.

These macroflocs promote enhanced biological phosphorous removal and very low sludge volume indices and the simultaneous carbon oxidation and nitrification / denitrification in one basin enables shorter cycle times and eliminates the need for a separate denitrification treatment stage. The te-cycTM process provides enhanced phosphorous removal to achieve more stringent phosphorous effluent values without the need for an additional solids removal treatment stage.

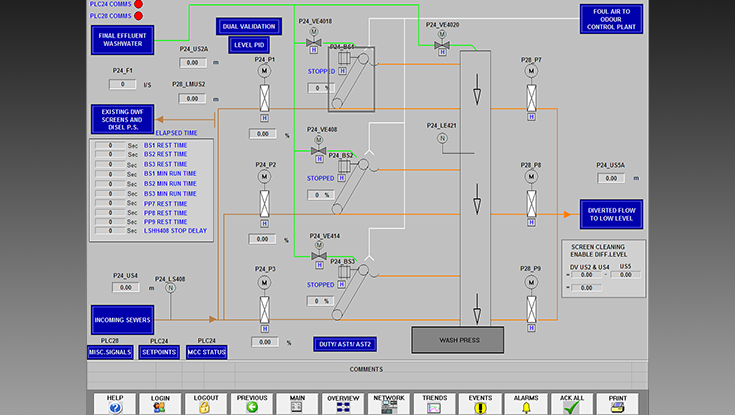

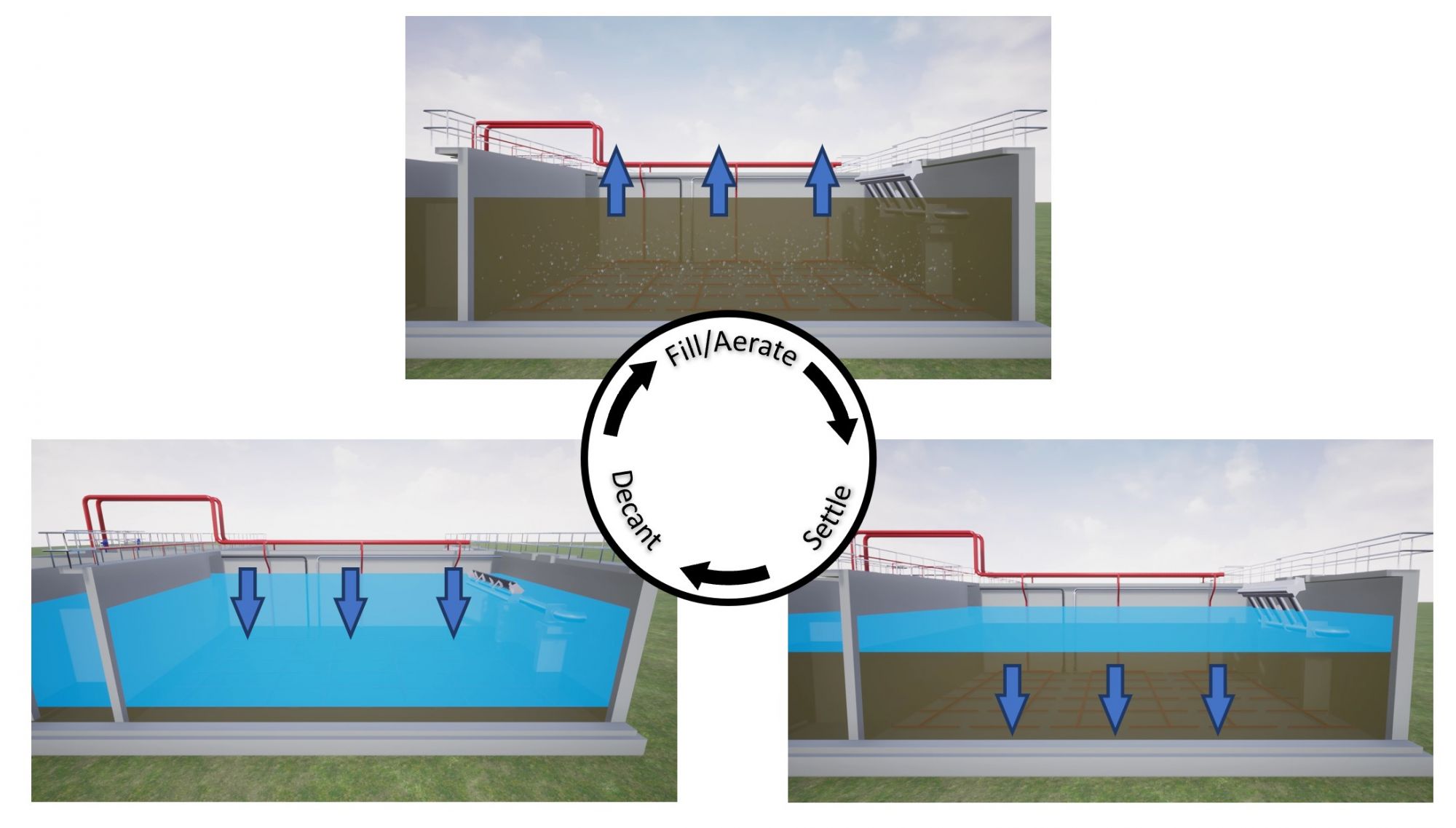

The process is broken down into three distinct phases that operate on a cycle:

fill/aerate – flow enters the aerated zone from the anaerobic reactor, aeration is controlled by the OUR control system and a portion of the sludge is constantly recycled to the inlet of the selector.

settle – the inlet to the basin is closed, the aeration and internal recycle is stopped and the sludge aggregates as a blanket and settles to the base of the reactor basin.

decant – a moving decanter removes approximately one third of the reactors clear treated effluent, the decanter has an integral scum guard to prevent any floating solids from discharging.

The te-cycTM process incorporates advance process control by means of OUR (Oxygen Uptake Rate). The OUR real time control (RTC) system determines the time and intensity of aeration according to the degree of pollution in the wastewater, ensuring efficient operation of the plant and reduced operational cost.

Find out more about Phosphorus Removal

Contact Us for more information or to talk about your requirements email enquiries@te-tech.co.uk

Download out te-cycTM brochure

|

Small footprint |

Process security & resilience |

|

No requirement for primary or tertiary treatment |

Low suspended solids |

|

Single stage treatment |

Nitrate & Phosphorous removal |

|

Low chemical consumption |

Ammonia removal |

|

Low whole life cost |

Resistant to flow & load fluctuations / toxic shock |

Project Details

Southern Water supplies 2.7 million customers 542 million litres of water per day from 84 treatment works.

The wastewater from 4.7 million customers or 745 million litres per day is treated at 367 wastewater treatment works.

Hawkhurst South Key Figures

Process Solution te-cycTM

Population equivalent 2285

Max Flow Rate 65m3/hr

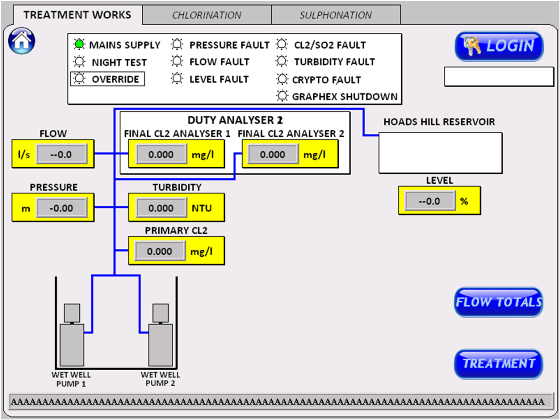

Ave COD < 125mg/l

Ave BOD < 10mg/l

Ave SS < 5mg/l

Total P < 0.3mg/l

Ave Ammonia < 1mg/l

Total Iron < 4mg/l

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)