The te-sewpasTM technology is a reliable, low cost and efficient desludging system for primary and final settlement tanks. Simplicity of operation and minimal operator intervention provides significant benefits compared to traditional manual desludging systems.

At Stocksbridge, a single Type B te-sewpasTM unit with duty/standby air blowers serves the two humus tanks. Rather than using the standard control panel, MMB decided to integrate the te-sewpasTM controls into the central PLC and Te-Tech provided a functional design specification for this purpose. The project was completed in October 2019.

“We’ve been using the air lift systems of various makes on our sites for the last 20-25 years”, says Yorkshire Water’s Wastewater Asset Planning Sponsor, Jan Buczylo.

“The te-sewpasTM is particularly robust and we decided to retrofit additional systems in place of conventional progressive cavity pumps at both Stillington and Sutton-on-the-Forest.”

Installation of these two systems were completed in April 2021.

Process Description

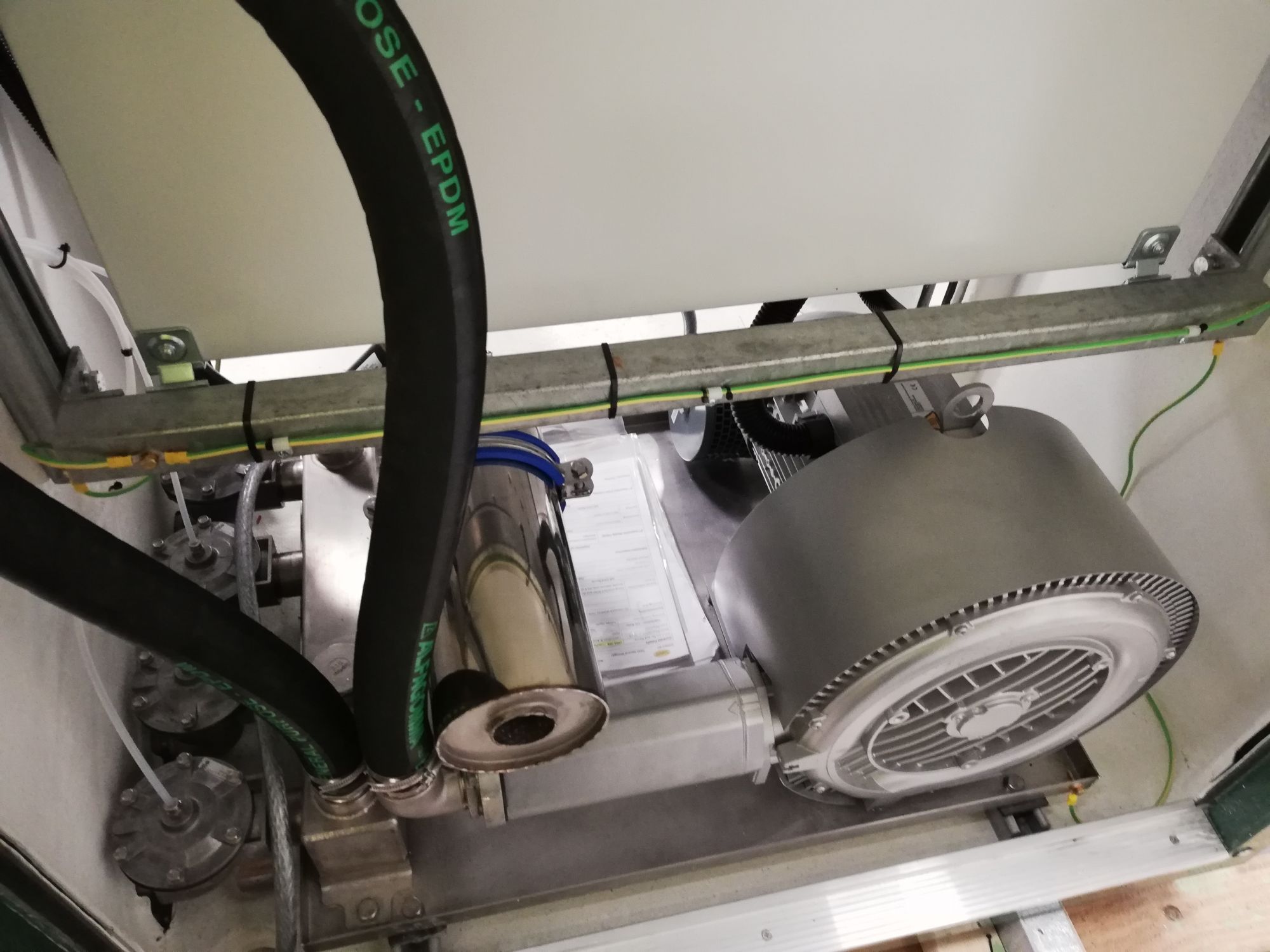

The te-sewpasTM desludging system is a self contained unit which operates on the principle of an intermittent air lift. Adjustable timers incorporated within the control panel operate a solenoid valve fitted in the air discharge pipework. This controls the amount of air delivered to the sludge discharge pipework and the time delay between desludging events.

Each charge of air lifts a quantity of sludge and discharges from the sludge discharge pipe, whilst the variable delay ensures that sufficient time elapses for the sludge to recover or refill the sludge pipework, without causing ‘rat-holing’.

A multi-timer incorporated within the Control Panel, enables the unit to be programmed to desludge at any selected interval to satisfy the specific needs of each site. The system can also be operated and monitored remotely by the client’s control system.

The te-sewpasTM is available as a 1, 2, 3 or 4 way unit, with individual on/off control. Manual operation is also available for instant desludging when required.

Read our news article HERE - Airlift System Delivers on Desludging

Download our brochure HERE

Case Study and More Information

.jpg)