Te-Tech Process Solutions can provide effective advanced wastewater treatment solutions for commercial clients seeking to achieve Nitrate Neutrality on new developments and for municipal and industrial clients who require enhanced biological phosphorus removal to achieve tightening P consents on existing and new treatment works.

Phosphorus is a naturally occurring nutrient for life and essential for all living organisms. Phosphates and nitrates promote plant growth and are therefore commonly used in fertilisers, but can also be found in detergents, food residues and waste. Excessive amounts of nutrients in water bodies can however lead to eutrophication creating toxic and anoxic conditions that are fatal or harmful to fish and other aquatic life.

Acceptable phosphorus discharge consent levels have become increasingly stringent over the years, enforced through progressive legislation. The Environment Agency, through the Water Industry National Environment Programme have identified over 900 wastewater treatment plants where a range of phosphorus consents, some as low as 0.01mg/l, will come into effect before 2025.

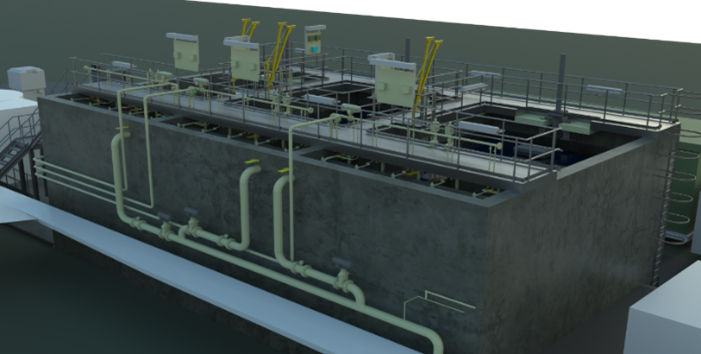

Te-Tech Process Solutions are able to provide an efficient, sustainable and cost effective solution for biological phosphorus removal, to achieve stringent P consents to below 0.3mg/l. The te-cycTM process, with over 500 reference plants around the world, is a cyclic activated sludge process achieving simultaneous carbonaceous, nitrification, denitrification and biological P removal, applicable for ammonia, total N and Total P consents with the versatility to be applied as a single stage replacement of existing multi stage treatment assets, or as a side stream to satisfy growth drivers in addition to tightening consent standards.

The te-cycTM process is a simple, efficient, low operational cost solution available as a bespoke design in concrete tanks or in a range of standard off site manufactured packaged units to suit different sizes and applications.

Standard package units have been specifically designed for developer needs to address Nitrate and phosphorus and water companies looking for cost effective, reliable and simple solutions for small to medium size plants and rural locations. These standard modular units come as a complete ‘plug and play’ system including access platforms, aeration blowers, chemical dosing and local control panels for automated operation.

Medium to large sites can be catered for with multiple units or streams or larger process units adopting larger glass coated steel or concrete tanks, such arrangements are particularly suitable where there may be seasonal variations in flow and load or alternatively where operational flexibility is required or where flows may be phased or incremental as developments progress.

Read about Phosphorus Removal

Read our news article HERE - A Sustainable Approach to Phosphorus Removal