Water companies from Northumbrian to Southern are seeing the advantages of airlift pumping for sludge handling. Airlift pumps are, of course, not new but when coupled to a modern PLC controller, offer many advantages over progressive cavity pumps.

What is te-sewpas™?

Te-sewpas is a reliable, low cost and efficient desludging system for primary and final settlement tanks. Based on a typical desludging programme of four times per day, pulsed airlift units will reduce power costs by about 25% and give a similar saving in maintenance expenses.

How does the technology work?

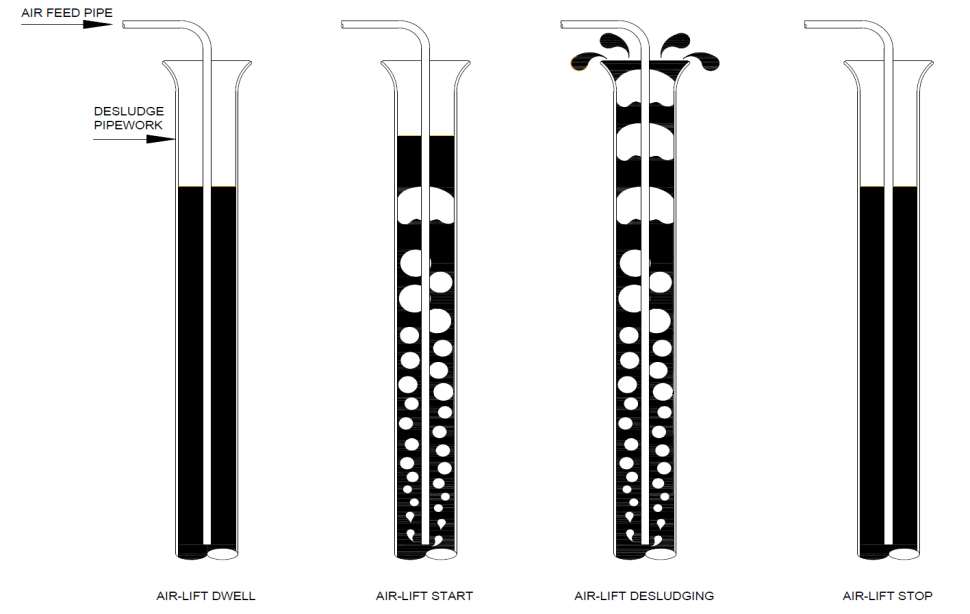

The te-sewpas desludging equipment is a self-contained unit which operates on the principle of an intermittent air lift. A blower generates pressurised air which is fed as intermittent slugs into the bottom of a pipe full of sludge. The air rises because of its buoyancy and carries a slug of sludge with it to discharge at the top of the pipe.

This gentle lifting action imparts minimal shear to the sludge, minimising floc break up and preserving dewaterability. Unlike other types of pumps, there is no suction, so rat-holing is eliminated. Adjustable timers incorporated within the control panel operate a solenoid valve fitted in the air discharge pipework. This controls the amount of air delivered to the sludge discharge pipework and the time delay between desludging events.

This gentle lifting action imparts minimal shear to the sludge, minimising floc break up and preserving dewaterability. Unlike other types of pumps, there is no suction, so rat-holing is eliminated. Adjustable timers incorporated within the control panel operate a solenoid valve fitted in the air discharge pipework. This controls the amount of air delivered to the sludge discharge pipework and the time delay between desludging events.

Each slug of air lifts a quantity of sludge and discharges from the sludge discharge pipe, whilst the variable delay ensures that sufficient time elapses for the sludge to recover or refill the sludge pipework, to ensure consistent desludging. A multi-timer incorporated within the controls enables the unit to be programmed to desludge at any selected interval to satisfy the specific needs of each site.

The system can also be operated and monitored remotely by the client’s SCADA system. The te-sewpas can handle both primary and secondary sewage sludges and it is fully automatic with high reliability making it suitable for unmanned works.

Whilst te-sewpas is the first choice for new builds, it can be easily retrofitted to replace existing pumped desludging systems, providing significant capital and operational cost savings.

Even more efficiency with the 2nd Generation

The second generation te-sewpas is fitted with a more powerful, energy efficient air blower. The actuated air valves now have open/close limit switches to provide feedback to the PLC. The control software has been redesigned to provide more sophisticated control with a larger HMI screen and pressure monitoring instrumentation to shut down the air blower on high pressure and to provide an alarm on the HMI when the blower inlet filter needs cleaning.

The GRP enclosure is larger with a removeable side panel to allow better maintenance access to the air valves, and a removeable rear panel that allows the air blower to be safely removed.

The new generation of te-sewpas is a completely self-contained unit with a PLC based control system that can operate either as part of a Distributed Control System or as a stand-alone unit. It can be located close to the tanks that it serves with flexible air delivery hoses routed through ducts to each of the desludge chambers.

The air delivered is hot and hence there is no need for thermal lagging or insulation. Each te-sewpas unit can serve up to four primary or humus tanks with typical individual air delivery hose length up to 35 metres.

Call us on +44 (0) 2382 351600 or enquiries@te-tech.co.uk