When Portsmouth Water needed an emergency Cryptosporidium inactivation treatment process at one of their water treatment works, they turned to their AMP7 and Non-Infrastructure Framework Contractor, Trant Engineering, to design, build, install and commission a suitable system and return the works to full operation within 13 weeks. Te-Tech’s specialist team of controls engineers were on hand to help deliver the system integration.

Ultra Violet disinfection was identified as the preferred solution and a portable containerised UV treatment unit was selected. Integrating the UV treatment process into the existing works operation and within the limited site space was a significant challenge.

Dive into the PLC Integration

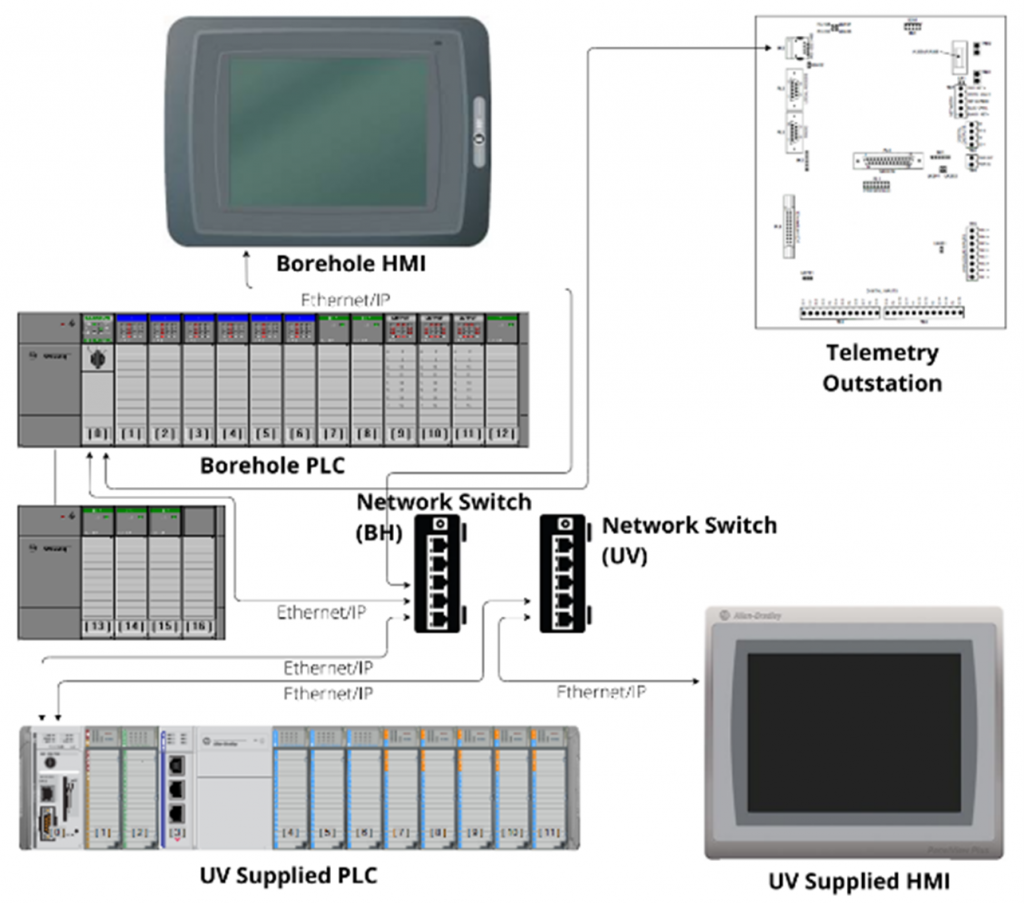

The containerised UV system had its own local Compact Logic PLC and motor control centre (MCC), controlling duty and standby UV reactor streams, and this had to be integrated into the existing WTW control system which utilised an Allen Bradley PLC, providing overall control of the abstraction, treatment and water quality monitoring systems. The maximum works flow was too high for a single UV reactor, so the control system had to be changed from duty/standby to duty/assist configuration. This alteration enabled a single UV reactor to operate within a defined flow and water quality range. If the single reactor failed the second reactor would resume control allowing the continuous compliant production of wholesome water. At high flow rate or if water quality deteriorates the system automatically reverts to duty/duty mode, allowing both UV reactors to operate in parallel splitting the load equally between the two.

Integrating the signals from the UV treatment control system with that of the existing works was the next challenge for the Te-Tech team. The integration of the network architecture of the two control systems could be designed, tested and proven. The solution integrated the two PLC control system via Ethernet/IP as shown in the system architecture schematic (Figure 1).

As part of the integration package, Te-Tech modified the human machine interface (HMI) to allow key parameter and asset performance to be monitored easily. Operational flexibility was provided by allowing Operators to log in and change some parameters, such as setpoints and alarm limits. However, changes to parameters outside of the designed work and operating window were protected, ensuring that there were no water quality or treatment breaches. Key operational and performance data was retransmitted to Portsmouth Water’s remote telemetry system. This activity utilised the same communications network, by the programming and configuration of a remote telemetry outstation and user terminals, via a Schneider ClearSCADA platform.

Experience Shines Through

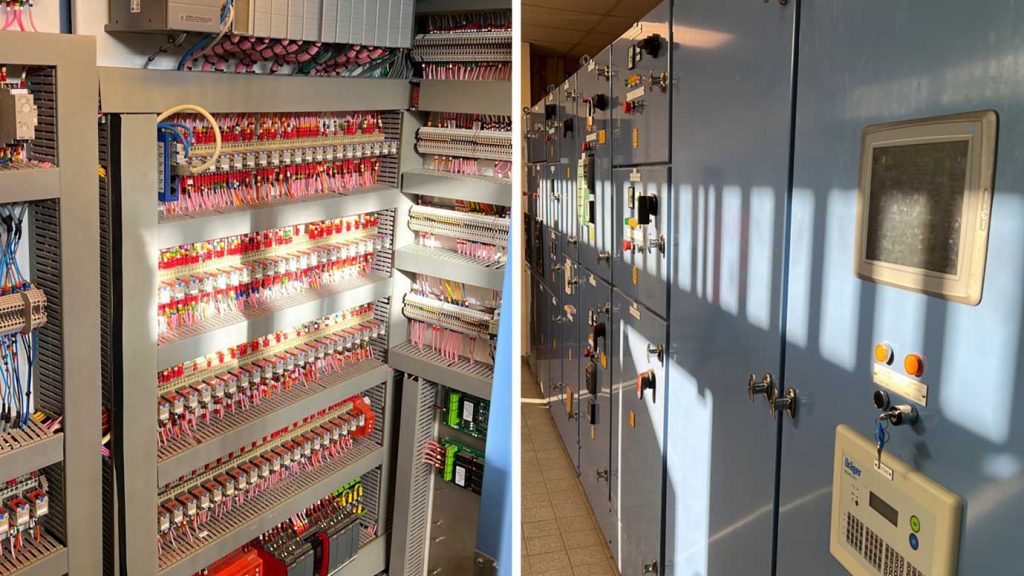

Te-Tech’s wide range of experienced electro-mechanical engineering and software programming talents, enabled all the required cabling, integration hardware and ancillaries to be designed, installed and tested in an efficient and professional manner. Their involvement in the project ensured that the implemented solution achieved the project’s objective, and Portsmouth Water was able to return the works to operation with a validated Cryptosporidium treatment process within the project period and before the increased summer demand.

Find out for by emailing our Technical Services Manager, Matt Head