Wastewater Treatment and Automation & Control System specialists, Te-Tech Process Solutions, install and integrate te-ionᵀᴹ advanced oxidation technology to suppress sludge bulking at Severn Trent Water’s Chipping Campden Sewage Treatment Works

Chipping Campden is a picturesque town located in the Cotswold district of Gloucestershire. In the summer months, tourists flock to the area and, naturally, make use of the many restaurants, cafes, and accommodation. The hospitality industries produce wastewater with high levels of fats, oils, and grease (FOG), much of which is discharged to the sewer network before making its way to the local sewage treatment works, Severn Trent Water’s Chipping Campden Sewage Treatment Works.

Trouble at the Works

The Severn Trent’s treatment works uses a conventional activated sludge process, and this is very efficient at meeting its discharge consent for biochemical oxygen demand (BOD), but the high levels of FOG in the tourist season results in the proliferation of filamentous bacteria, principally Nocardia spp, which cause poor sludge settling. This phenomenon, called “sludge bulking”, can lead to difficulty in meeting the total suspended solids (TSS) consent.

The Bugs

Under normal conditions the growth rate of filamentous bacteria like Nocardia, Microthrix, Trichococcus, Gordonia and Thiothrix is lower than that of floc forming bacteria, and their presence helps to stick flocs together to produce readily settleable flocs. However, when FOG levels are high the high surface area to volume ratio of the filamentous bacteria gives them a feeding advantage and they become dominant. This results in low density flocs which do not settle easily and form a blanket of foam on the surface of the final settlement tank. This is carried over into the treated effluent increasing the TSS concentration.

Tackling the Problem

The traditional solution to sludge bulking is the addition of polyelectrolytes to improve floc settlement, nutrients and selected bacteria supplements to boost floc forming bacteria growth. An alternative is to “cull” the filamentous bacteria to manage their population at a level where they are useful by dosing chlorine into the return activated sludge (RAS) line to kill the filamentous growth. The filaments extrude from the surface of the sludge floc and are therefore exposed and susceptible to the chlorine, but the dose rate has to be carefully controlled so as to destroy the filamentous bacteria without affecting the sludge floc. Whilst chemical dosing is an effective way of solving the bulking sludge problem, it has a number of issues, including ongoing chemical costs and health and safety risks. It is neither environmentally friendly nor sustainable. In order to avoid these issues, Severn Trent opted to install an innovative alternative technology for bulking sludge suppression, the te-ionTM process provided by Te-Tech Process Solutions. The te-ionTM advanced oxidation process destroys filamentous bacteria without the use of chemicals.

The Non-Chemical Option

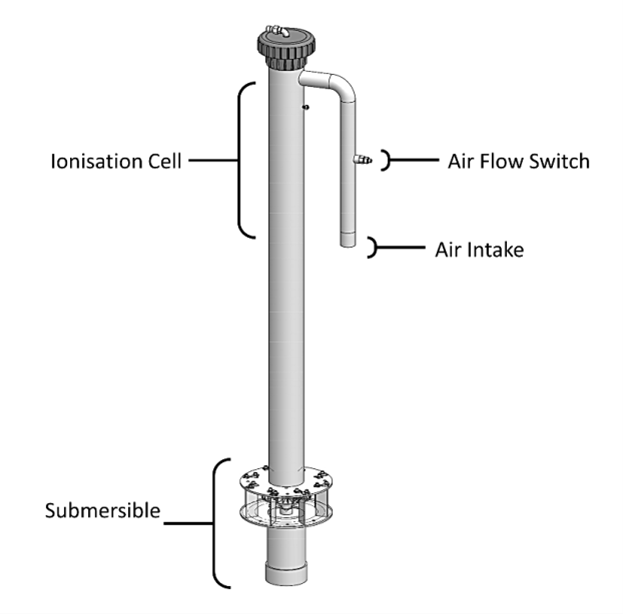

Filamentous bacteria are particularly susceptible to reactive oxygen species (ROS) like peroxide, ozone and free hydroxyl radicals the te-ionTM is an advanced oxygen process (AOP) that is used for a variety of drinking water and wastewater treatment applications including active pharmaceutical ingredient destruction, heavy metal removal, and disinfection. A single te-ionTM unit consists of an ionisation cell connected to a submersible turbine. As the turbine spins, air from the atmosphere is drawn through the ionisation cell where it passes over electrodes that generate a number of ROS in the form of a non-thermal plasma. This plasma is then distributed into the liquid in the aeration tank as fine bubbles via the turbine, where it then reacts with the pollutants to be removed. In the case of Chipping Campden STW and bulking sludge suppression, the non-thermal plasma removes the filaments in a similar way to the conventional chlorine dosing, but without the ongoing chemical costs and health and safety concerns. In addition, the energy consumption of the te-ion™ process is low.

Successful Installation

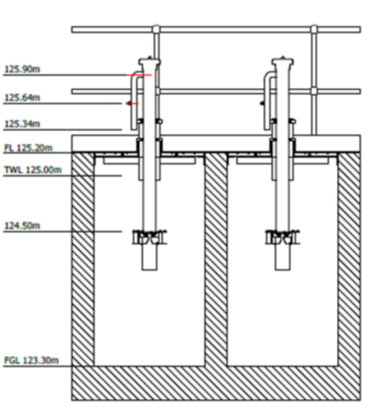

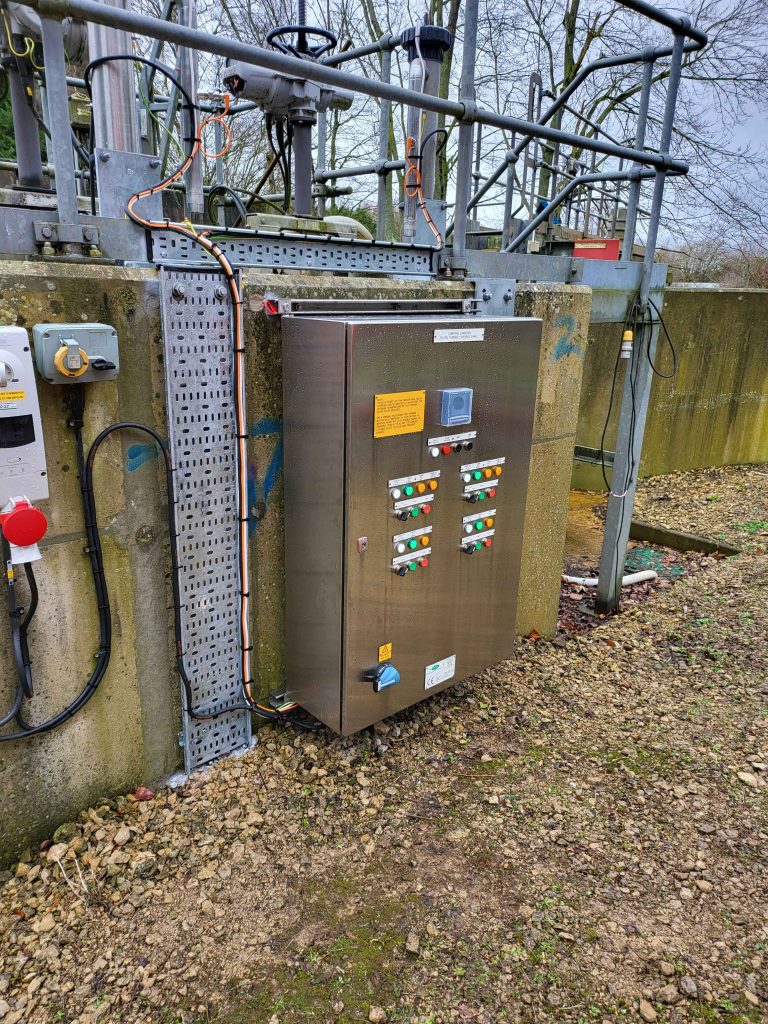

The installation at Chipping Campden STW was straightforward, with two te-ionTM units being mounted within the RAS chamber and connected to a local control panel installed nearby. The te-ionTM units, wall fixings, and surrounding floor grating were all manufactured and assembled offsite in the workshop to reduce the duration and complexity of onsite installation. Commissioning of the units has recently taken place and now they are ready to suppress the rapid growth of Nocardia when the problem arises in the summer months.